Fiberglass Reinforcement is a new material for construction. It combines lightness, strength, and durability. This makes it better than regular steel.

The main advantage of this reinforcement is its high strength. It can withstand up to 1200 MPa, which is 10 times more than steel. This means that less material is needed for construction.

Fiberglass Reinforcement is very lightweight, making it easier to transport and install. Its density is only 1.9 g/cm³, which is 4 times less than that of steel.

Key Advantages

- High tensile strength

- Lightweight material

- Corrosion resistance

- Service life of over 80 years

- Low cost compared to steel

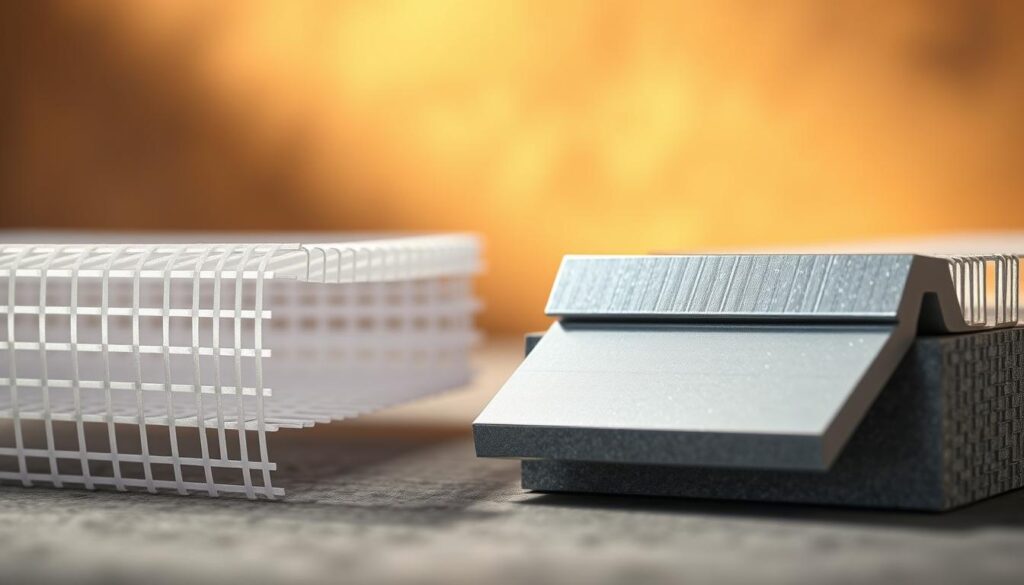

What is Fiberglass Reinforcement?

Non-metallic reinforcement is a new material for construction. It replaces traditional metal reinforcement. Fiber composites are gaining popularity due to their characteristics.

- Round cross-section rod

- Spiral thread made of fiberglass

Structure and Production

The creation of non-metallic reinforcement includes several stages:

- Preparation of aluminosilicate glass

- Forming rods

- Winding fiberglass

- Impregnation with polymer resin

Fiber composites combine lightness with high strength. Fiberglass, impregnated with a special resin, creates a reliable structure that withstands significant loads.

| Characteristic | Value |

|---|---|

| Guaranteed durability | Over 80 years |

| Specific weight | 5 times lighter than metal |

| Tensile strength | Exceeds steel reinforcement by 3 times |

An innovative approach creates effective building materials. They meet modern requirements.

What is Fiberglass Reinforcement?

When choosing materials for concrete reinforcement, it is important to select the right one. Fiberglass reinforcement is becoming increasingly popular. It has unique properties that distinguish it from conventional building materials.

Comparison Characteristics

Let’s look at the main differences between fiberglass and metal reinforcement:

| Parameter | Composite Reinforcement | Metal Reinforcement |

|---|---|---|

| Tensile Strength | Exceeds steel by 3 times | Standard strength |

| Weight | 5 times lighter | Heavier |

| Corrosion Resistance | High (up to 80 years) | Low |

| Electrical Conductivity | Dielectric | Conductor |

In comparative building materials, fiberglass reinforcement shows significant advantages.

- Reinforcement diameter: from 4 to 32 mm

- Supply length: 50-200 m.p.

- Installation savings due to the lightweight material

Important! The choice of reinforcement depends on the construction conditions and the technical requirements of the project.

Advantages of Fiberglass Reinforcement

Polymer composites are changing construction. They offer new ways to reinforce buildings. Fiberglass rods have features that change design.

Fiberglass reinforcement combines lightness with strength. Research shows its advantages:

- Weight is 8 times less than steel reinforcement

- Tensile strength up to 1000 MPa

- Service life of over 80 years

Technical Strength Characteristics

Comparing properties shows the advantages of polymer composites:

| Parameter | Steel Reinforcement | Fiberglass Reinforcement |

|---|---|---|

| Tensile Strength | 390 MPa | 1000 MPa |

| Specific Weight | 7800 kg/m³ | 980 kg/m³ |

| Service Life | 40-50 years | 80-90 years |

Fiberglass rods allow for the creation of lightweight structures. Their low weight facilitates transportation and installation. This saves money on construction.

Innovation in building materials is not a luxury, but a necessity of modern construction.

Advantages of Fiberglass Reinforcement

Reinforcement of structures with alternative reinforcement has unique properties. It is highly resistant to corrosion. This makes it very attractive for modern construction.

Corrosion Protection of Building Materials

Fiberglass reinforcement withstands aggressive environments very well. It does not deteriorate like traditional metal reinforcement:

- Withstands the alkaline environment of concrete

- Does not oxidize when in contact with moisture

- Maintains strength in harsh climatic conditions

Research shows that the service life of such reinforcement can be up to 85-90 years. This makes it a reliable option for reinforcement.

Fiberglass reinforcement operates from -70 to +100 degrees Celsius. This property is especially valuable for structures near the sea, in chemical manufacturing, and other aggressive environments.

The corrosion resistance of alternative reinforcement is a key factor in its advantage over traditional materials.

Advantages of Fiberglass Reinforcement

Non-metallic reinforcement made of fiberglass is becoming increasingly popular in construction. It has unique properties. They provide high strength for buildings and minimal impact on the environment.

- Minimal environmental impact during production

- Complete recyclability of the material

- Absence of harmful emissions during operation

- Low energy intensity of the production process

Environmental Friendliness of Production and Operation

Composite reinforcement is very eco-friendly. With proper calculation, the amount of waste can be reduced to almost zero. It does not emit harmful substances and helps create stronger buildings.

Statistics show that buildings with fiberglass reinforcement last longer. Its service life can be 2 or more times longer than traditional materials. This reduces the burden on the environment.

The use of fiberglass reinforcement is not just a technological solution. It is a step towards more sustainable construction.

Areas of Use for Fiberglass Reinforcement

Modern construction is looking for new ways to create strong buildings. Composite reinforcement made of fiberglass is a new solution. It provides unique opportunities for various construction projects.

Fiberglass reinforcement is used in many construction projects:

- Reinforcement of foundations of private houses

- Strengthening load-bearing walls

- Reinforcing concrete slabs

- Construction of small architectural forms

Features of Use in Construction Structures

Reinforcement of concrete with composite reinforcement has many advantages. The lightness of the material significantly reduces the load on the structures. Statistics show that fiberglass reinforcement weighs only a quarter of the weight of steel.

Composite reinforcement is ideal for harsh climatic conditions. It is resistant to corrosion, has high strength, and a service life of over 100 years. This is especially important for regions with aggressive environments.

GFRP provides maximum utility for all participants in the construction process, adhering to the principles of sustainable construction.

Among the key advantages of composite reinforcement, the following should be highlighted:

- Low thermal conductivity

- Resistance to electromagnetic influences

- Minimal transportation costs

- Ease of installation

Fiberglass reinforcement is becoming increasingly popular in modern construction. It adheres to the principles of innovation and efficiency.

Areas of Use for Fiberglass Reinforcement

Building materials are constantly changing. Architects and engineers are gaining new opportunities to create unique structures. Fiberglass reinforcement, for example, has found application in many fields, including sports.

Innovations in Sports Construction

Sports facilities require special materials. They must be lightweight, strong, and durable. Fiberglass reinforcement is ideal for such projects due to its special characteristics:

- Extremely high strength compared to other materials

- Low weight, facilitating installation and transportation

- Resistance to corrosion and atmospheric effects

In the design of sports facilities, fiberglass reinforcement is increasingly used. It has unique properties that help create complex shapes with minimal costs.

Statistics confirm that the use of fiber composites is very promising. The service life of fiberglass reinforcement can exceed 100 years. This makes it very attractive for long-term projects.

The expected service life of GFRP significantly exceeds the characteristics of traditional building materials. This ensures economic efficiency and reliability of structures.

Areas of Use for Fiberglass Reinforcement

Water supply and sewage systems require reliable materials. Polymer composites made of fiberglass are becoming a more popular choice for reinforcement.

Advantages of Use in Engineering Communications

Fiberglass reinforcement has unique properties. It is ideal for water supply systems:

- Complete resistance to corrosion

- High chemical inertness

- Service life of over 80 years

- Low thermal conductivity

Reinforcement of structures of water pipelines with fiberglass reinforcement ensures long-term reliability. It also reduces maintenance costs. The material is not affected by aggressive liquids, ensuring the stability of the networks.

Composite reinforcement can withstand high loads and maintain its properties for decades.

The lightweight and ease of installation make polymer composites attractive for water management projects. The use of such reinforcement allows for significant reductions in construction and operational costs.

Disadvantages of Fiberglass Reinforcement

Every building material has its peculiarities. Fiberglass rods are no exception. It is important to consider economic aspects when planning construction projects.

Cost Characteristics of Composite Reinforcement

Investors often debate the cost of reinforcement materials. Fiberglass reinforcement has its pricing peculiarities:

- Initial price is 30-50% higher than metal reinforcement

- Long-term savings amount to up to 70% of costs

- Lower transportation costs due to lightweight

- Service life of over 80 years

- Low operational costs

- Absence of corrosion damage

“Investments in quality fiberglass rods pay off within the first years of operation”

Although the initial cost is higher, composite reinforcement proves to be economically advantageous. This is due to its long service life and minimal maintenance costs.

Disadvantages of Fiberglass Reinforcement

Fiberglass Reinforcement has its limitations when reinforcing concrete. It is not suitable for all construction structures.

- Temperature limitations: The material loses properties at high temperatures

- Low modulus of elasticity

- Difficulty in joining and fastening

- Limited application in load-bearing structures

Critical Impact Factors

Fiberglass reinforcement operates from -15°C to +160°C. This limits its use in extreme conditions. When heated, it loses up to 50% of its properties.

Additional limitations include:

- Inability to withstand high dynamic loads

- Sensitivity to direct mechanical impacts

- Narrow application range in capital construction

Experts advise using fiberglass reinforcement in lightweight structures. Avoid important engineering structures.

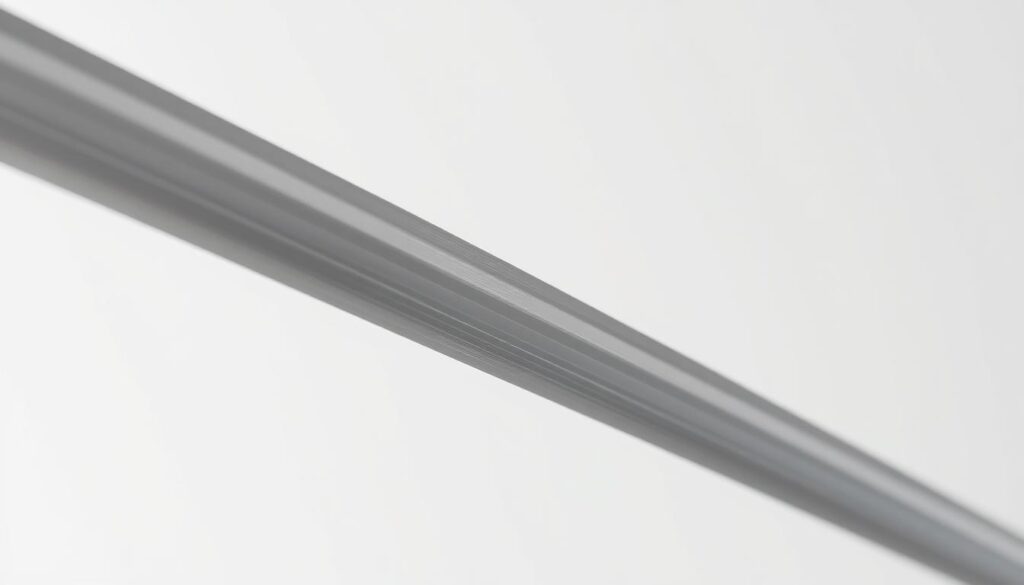

Technology for Producing Fiberglass Reinforcement

The production of fiberglass reinforcement is a complex process. It began in 2010. Thin threads made of fiberglass are used for this.

Special polymer components are used to manufacture the reinforcement. The rods have a diameter of 0.4 to 1.2 cm. They are produced in rolls of 100 meters.

Modern pultrusion technologies enhance the corrosion resistance and strength of the reinforcement. This has made it a primary material for construction.

FAQ

What is Fiberglass Reinforcement?

Fiberglass reinforcement is a modern material for construction. It consists of glass fibers coated with polymer resin. This material is very strong, lightweight, and does not rust.

How does Fiberglass Reinforcement differ from Metal?

Fiberglass reinforcement is not heavier than metal. It is better resistant to corrosion, does not conduct electricity, and has a long service life.

Where is Fiberglass Reinforcement most commonly used?

It is often used in construction. Especially in sports facilities, water systems, foundations, and walls. Also in places where corrosion resistance is needed.

What are the main advantages of fiberglass reinforcement?

Its advantages are lightness, strength, corrosion resistance, and low thermal conductivity. It does not conduct electricity and does not harm the environment.

Does fiberglass reinforcement have disadvantages?

Yes, the disadvantages include a higher price than metal. It does not withstand high temperatures and dynamic loads. It is also important to connect it properly.

How durable is Fiberglass Reinforcement?

Its service life is up to 100 years. It is very resistant to corrosion and can operate in harsh conditions.

How does fiberglass reinforcement affect the environment?

Its production is more energy-efficient than that of metal. It does not emit harmful substances. This contributes to the creation of eco-friendly buildings.

Can fiberglass reinforcement be used in all types of structures?

No, not in all. It is not suitable for structures with high loads, high temperatures, or for electrical conductivity.

How is fiberglass reinforcement installed?

Installation is similar to metal but requires special actions. It is important to connect it properly, avoid damage, and follow instructions.