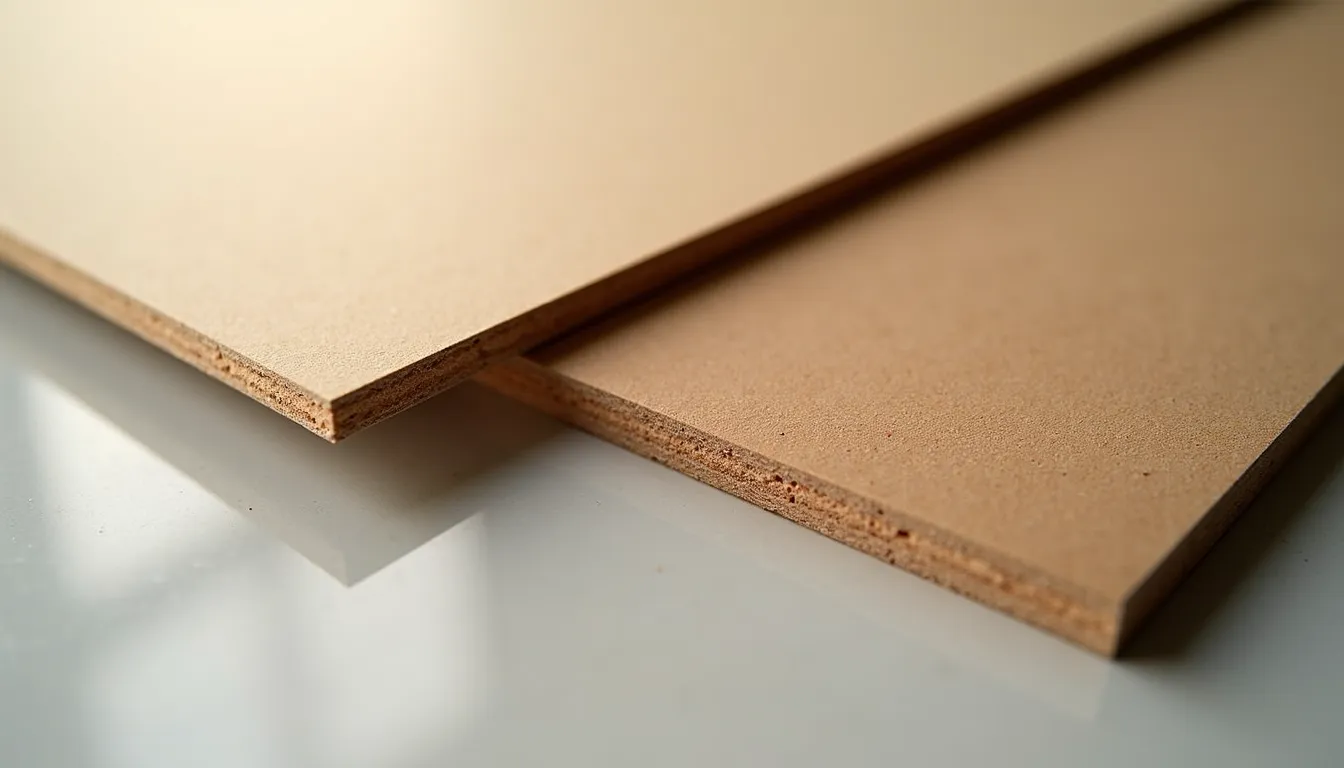

When choosing between particle board (DSP) and medium-density fiberboard (MDF), it is important to understand how these two materials differ from each other in order to make the right choice for your needs. Both materials have their advantages and disadvantages, and their use depends on the specific requirements of the project.

Particle board (DSP) is made from wood chips that are glued together using resins and formed under high pressure. Because of this, the production process of DSP is cheaper, making it a popular choice for furniture manufacturing and construction. Since DSP is usually covered with veneer or laminated film, it can imitate real wood, making it aesthetically appealing to consumers. However, it is worth noting that DSP is less resistant to moisture and can easily deform in humid conditions.

Medium-density fiberboard (MDF) is made from wood fibers that are also glued together, but the manufacturing process uses a method that provides a more uniform texture. MDF is characterized by high density and smoothness of the surface. This makes it an ideal option for painting or veneering. MDF is less sensitive to deformation from moisture; however, it can still be affected by water if not properly protected.

| Characteristic | DSP | MDF |

|---|---|---|

| Price | Lower | Higher |

| Water resistance | Low | Medium |

| Resistance to mechanical damage | Medium | High |

| Weight | Lighter | Heavier |

| Ease of processing | Medium | High |

It is important to consider not only these characteristics but also the environmental impact of both materials. For example, DSP can emit formaldehyde, especially in the first years of use, so when choosing a material for residential spaces, it is worth paying attention to quality certificates. MDF, on the other hand, is often considered a more environmentally friendly option, as it uses fewer harmful substances in its production.

Thus, when choosing between DSP and MDF, it is important to consider not only the price and characteristics but also the purpose of the material, operating conditions, and environmental aspects to make the best choice for yourself.

Production of DSP and MDF

The process of manufacturing particle board (DSP) begins with selecting raw materials, which consist of wood chips, splinters, and sawdust. These waste materials are processed, cleaned of contaminants, and then mixed with specific resins that serve as glue. After that, the mixture is formed into boards, which are pressed under high pressure and temperature. As a result of this process, a strong yet lightweight board is formed. At the final stage, DSP is covered with various materials, such as laminate or veneer, which allows giving the products the desired appearance.

The production of medium-density fiberboard (MDF) is carried out using a more complex technology. It uses wood fibers that are also glued together, but the technology involves grinding them to a finer state. The fibers are mixed with glue and then formed into boards, which are subjected to pressing. As a result, a smooth and homogeneous structure is obtained, making MDF ideal for processing, such as painting or veneering. This material, due to its density and ease of processing, is a popular choice for furniture and decorative elements.

It can be noted that, although the manufacturing processes of both materials are relatively simple, their technologies have unique features. DSP is characterized by low production costs, making it accessible for mass use. In contrast, MDF requires more quality control at all stages, as its production requires more resources and time.

Here are some key points about the production of DSP and MDF:

- Raw materials: DSP – wood chips, MDF – wood fibers.

- Manufacturing process: DSP is pressed from a mixture of chips and glue, MDF – from finer fibers.

- Cost: DSP is cheaper to produce than MDF.

- Quality and environmental friendliness: MDF usually has higher quality standards and lower content of harmful substances.

It should also be remembered that in Ukraine, the industry that produces DSP and MDF has significantly developed in recent years. Wood processing has become one of the important plans for sustainable development in the region, and new technologies help reduce environmental impact by eliminating the use of harmful components.

The production of both materials is regulated by the state, and manufacturers are actively working to improve environmental indicators, which is becoming increasingly relevant for the Ukrainian market. Although these two types of boards have much in common, they have mastered production strategies that determine their further characteristics and areas of use.

Characteristics and properties of DSP

Particle board, or DSP, has its specific characteristics and properties that make it a popular choice in the construction and furniture industries. First of all, one of the key aspects of DSP is its density. This material has medium density, which allows it to be lightweight compared to MDF; however, this lightness also means that DSP is less resistant to impacts and mechanical damage. This creates certain limitations in use, especially in places where furniture or other structures may be subjected to significant loads.

| Parameter | DSP |

|---|---|

| Density | Medium (600-800 kg/m3) |

| Moisture resistance | Low (possible swelling) |

| Thermal conductivity | Medium |

| Sound insulation | Medium (not excellent) |

| Ease of processing | Quite convenient |

Another important point is moisture resistance. DSP is not recommended for use in high humidity conditions, as this can lead to deformation and swelling. Usually, DSP boards are covered with protective materials that change their water resistance and make the panels less vulnerable; however, this cannot completely eliminate the risk. That is why DSP is not recommended for wet rooms, such as bathrooms or kitchens.

However, despite its disadvantages, DSP has a number of advantages that make it useful in many areas. For example:

- Cost: DSP is significantly cheaper compared to MDF, making it accessible for mass use.

- Versatility: DSP is used for making furniture, wall panels, flooring, and other interior elements.

- Ease of processing: Due to its structure, DSP is easy to cut, drill, and process, which simplifies the furniture manufacturing process.

Currently, DSP is widely used in Ukraine, as manufacturers are developing new technologies to improve quality and reduce negative environmental impact. Many companies have started using eco-friendly formaldehyde-free resins, which reduces harm to the health of people who come into contact with these materials.

Thus, despite some limitations, DSP remains an important material for the furniture and construction industries due to its affordability, ease of processing, and versatility of use.

Characteristics and properties of MDF

MDF has a number of characteristics that make it a unique and sought-after material in various fields. One of the main advantages is its high density, which gives the material strength and stability. MDF boards can have a density ranging from 600 to 900 kg/m3, making them much stronger compared to DSP, especially in conditions where it is important to prevent deformations.

Another important characteristic of MDF is its smooth and homogeneous surface. This allows for easy painting of the material or covering it with veneered or laminated materials. As a result, MDF is often used for making furniture and decorating interiors where aesthetic appearance is important. Due to these properties, MDF boards are often used to create complex shapes and designs, which is difficult to achieve with other materials.

| Parameter | MDF |

|---|---|

| Density | High (600-900 kg/m3) |

| Water resistance | Medium (requires protection) |

| Resistance to mechanical damage | High |

| Thermal conductivity | Medium |

| Sound insulation | Quite good |

| Ease of processing | High |

It should also be noted that MDF has quite high resistance to mechanical damage. This makes it an ideal choice for furniture that is subjected to daily loads, such as chairs or shelves. Although MDF may be more sensitive to moisture compared to moisture-resistant options (for example, MDF treated with protective coatings), it is still more resistant to deformations than DSP in similar conditions.

Notably, the sound insulation properties of MDF are another advantage. It can reduce noise levels, making it a popular choice for partitions or walls in residential spaces. Due to its dense and massive structure, MDF can help achieve a comfortable atmosphere in home conditions.

Along with these positive characteristics, it is important to consider the environmental aspects. Modern MDF manufacturers are increasingly trying to use formaldehyde-free resins, which reduces the emissions of harmful substances during operation, which is an important factor for consumers concerned about health and ecology.

In conclusion, MDF can offer not only aesthetics but also practicality in use, thanks to its unique properties, making it an attractive choice for many applications in construction and furniture manufacturing.

Advantages and disadvantages of DSP

Particle boards (DSP) have their specific advantages and disadvantages that are worth considering in detail to understand why they remain a popular choice in the market. One of the key advantages of DSP is its cost. This material is significantly cheaper compared to other materials, such as MDF or natural wood, making it accessible for many consumers. Considering the realities in Ukraine, this is especially important for consumers looking to save without compromising quality.

DSP also demonstrates versatility in use. It can be found in furniture, partitions, wall panels, and flooring. Many Ukrainian furniture manufacturers use this material to create inexpensive yet stylish solutions that fit well into various types of interiors. Additionally, DSP is easy to process—it can be cut, drilled, and treated, which significantly simplifies the furniture manufacturing process.

However, despite numerous advantages, there are also disadvantages that need to be considered. One of the main limitations is moisture resistance. DSP has low water resistance, making it unsuitable for use in wet rooms, such as bathrooms or kitchens. The use of protective coatings can somewhat increase its moisture resistance, but it is impossible to completely eliminate the risk of swelling.

Another disadvantage is mechanical characteristics. DSP is less durable compared to MDF, making it more susceptible to mechanical damage. This limits its use in places where it is subjected to significant loads. For example, furniture that is frequently moved or structures where there is a risk of impacts may not withstand loads if made from DSP.

| Advantages of DSP | Disadvantages of DSP |

|---|---|

| Low price | Low moisture resistance |

| Versatility of use | Threatening resistance to mechanical damage |

| Ease of processing | Possibility of deformation in high humidity conditions |

At the final stage, it is recommended to pay attention to the environmental aspects of using DSP. In modern production, formaldehyde-free resins are increasingly appearing, which reduce harmful emissions. When choosing DSP, consumers should pay attention to quality and environmental certificates, which is becoming increasingly important in the context of heightened health and safety requirements.

Thus, DSP offers a number of advantages, such as affordability and versatility, but also has significant disadvantages, including limited moisture and mechanical damage resistance. This makes it important to consider all these factors when choosing a material for specific needs.

Advantages and disadvantages of MDF

MDF has a number of clear advantages that make it a popular choice in the furniture and construction industries. One of the main advantages is its high density, which provides strength and stability. This material can withstand large loads without deformation, which is an important aspect for furniture or structures used in everyday life. MDF boards can have a density of up to 900 kg/m3, making them more reliable compared to less dense materials.

Another advantage is the smooth and homogeneous surface, which makes MDF particularly attractive for processing. It is easy to paint and cover with veneered materials, allowing for easy realization of aesthetic ideas. Thus, MDF is often used for producing high-quality furniture, including cabinets, chairs, and tabletops, where both appearance and durability are important.

MDF is also noted for its high resistance to mechanical damage. This means that furniture or other elements made from MDF can withstand daily use without significant damage. For example, tables and shelves made from this material are less prone to scratches or dents compared to softer materials like DSP.

Additionally, the sound insulation properties of MDF make it ideal for use in residential spaces where it is important to reduce noise levels. MDF boards can serve as effective sound insulation elements, which is especially useful for apartments in multi-story buildings.

However, despite numerous advantages, MDF also has some disadvantages. Its cost is higher than that of DSP, which can be a significant factor for budget projects. The higher price is due to production and raw material costs, which include the use of higher quality components in the manufacturing process.

MDF also has increased sensitivity to moisture. Even though it is more water-resistant compared to DSP, moisture and humidity should not be ignored. In cases where MDF boards have not been treated with appropriate protective coatings, this can lead to deformations upon contact with water, so it is important to protect them properly. Using moisture-resistant adhesive or lacquer can significantly improve the situation.

| Advantages of MDF | Disadvantages of MDF |

|---|---|

| High density and strength | Higher cost |

| Smooth and homogeneous surface | Sensitivity to moisture |

| Good sound insulation | Unsuitable for outdoor use without treatment |

| High resistance to mechanical damage | Heavy for transportation due to weight |

Thus, MDF offers many advantages, such as high mechanical characteristics and aesthetic appearance, making it an attractive option for furniture products. However, it is important to consider its disadvantages, such as cost and moisture requirements, to ensure long-term use and satisfaction with the finished product.

Areas of use for DSP and MDF

The areas of use for DSP and MDF vary widely, depending on their characteristics and properties. Both materials have found their place in the furniture industry, construction, and interior design. Let’s take a closer look at where these materials are used in Ukraine.

Particle boards (DSP) are typically used in the following areas:

- Furniture manufacturing: DSP is especially popular for making inexpensive furniture, such as chairs, tables, cabinets, and dressers. Its cost makes it an accessible option for many consumers looking for stylish and economical furniture.

- Construction and renovation: DSP is used for making partitions, walls, flooring panels, and other structures. Due to their light weight, the boards are easy to install and dismantle, making them popular in temporary constructions or cosmetic renovations.

- Interior design: DSP can be used to create decorative elements, such as shelves or wall panels. With various coatings, such as laminate or veneer, DSP can add an aesthetic appearance to any space.

In contrast, medium-density fiberboards (MDF) are typically applied in:

- High-quality furniture manufacturing: Due to its smooth and homogeneous surface, MDF is well-suited for painting and processing. This makes it an ideal choice for making furniture that will be used in residential spaces, where it is important to maintain aesthetic appearance.

- Interior decoration: MDF is popular for making doors, wall panels, moldings, and other decorative elements, as it can be processed to fit any interior style.

- Construction: MDF is used for making partitions and suspended ceilings, where it is important to ensure good sound insulation and aesthetic appearance.

It should be noted that in Ukrainian conditions, there is a growing interest in the environmental aspects of material selection. More and more manufacturers are trying to implement formaldehyde-free resins in production, making both materials less harmful to health and the environment. This is particularly important in the context of private homes and apartments, where ensuring the quality of materials is essential for comfortable living.

Thus, the choice between DSP and MDF should consider not only the characteristics and properties of the materials but also the specifics of their use in various areas. Depending on the project and desired outcome, both materials can be an excellent choice for your interior or construction.

Choosing between DSP and MDF: what to pay attention to

When choosing between DSP and MDF, it is important to pay attention to several key aspects. First of all, consider the purpose of the material. If it is about making inexpensive furniture for temporary use, then DSP can be an excellent option. However, for making furniture that should last longer and maintain its appearance, it is better to choose MDF, which has greater mechanical properties and good aesthetic qualities.

Another important point is the environmental friendliness of the chosen material. For those who care about health and safety, it is worth paying attention to quality certificates. In Ukraine, the trend towards using formaldehyde-free resins is becoming increasingly popular, so the availability of eco-friendly options for both materials is gradually increasing.

After determining the purpose and environmental friendliness, it is important to take into account the operating conditions. If you plan to use the material in wet rooms, DSP is not an optimal choice, while MDF with proper treatment may be more desirable. Decorative elements that will be subjected to significant mechanical loads will also require the use of MDF due to its high strength.

Here are some important points to consider when choosing:

- Cost: DSP is significantly cheaper than MDF.

- Durability: MDF is more resistant to mechanical damage.

- Processing: MDF is easier to process and provides a better aesthetic appearance.

- Moisture: MDF is better suited for wet rooms.

- Environmental friendliness: Pay attention to certificates and material compositions.

The choice between DSP and MDF requires a precise assessment of needs and project specifics. The right approach to selection can significantly affect the quality, durability, and appearance of your furniture and structures.